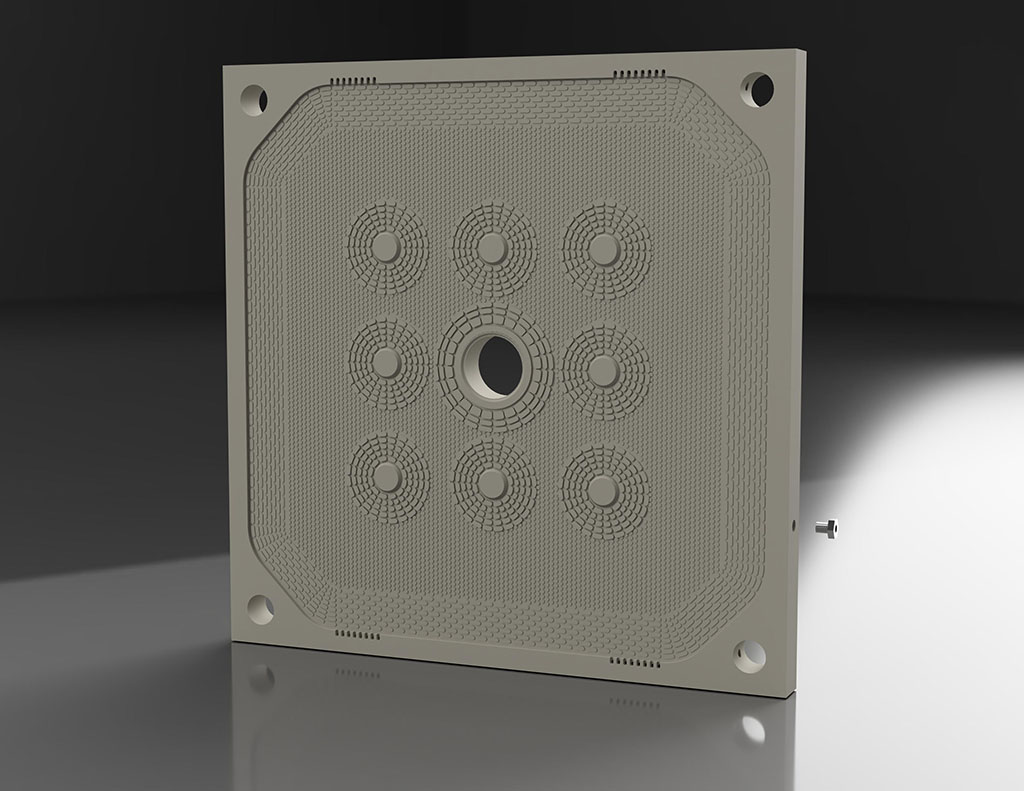

Jing Jin produces a complete set of Membrane Plates made by injection molding, ensuring an excellent product. Membrane Block Type is the best choice for reducing energy cost of the filter press. Working at low feed pressures we can obtain a higher dry quality in the chamber with the use of air or water to squeeze the membranes.

Unlike the classic filter press, the membrane is able to apply an even pressure over the entire cake surface. Consequently, we obtain better dry solids contents and a much more homogenous cake. These cakes are easier to unload because they contain fewer sticky, wet areas. Therefore, this type of filter makes it easier to adapt to polymer treatment conditions.

These types of plates have made the classic interchangeable membrane plates obsolete, outclassing them for mechanical and chemical resistance, and maintenance costs are significantly lower.

Basically we can summarize the advantages as below:

1. Reduce filtration times and costs.

2. Obtain a more dehydrated product with less effort.

3. Membrane plates bring super excellent filtration effect and unimaginable benefits.

The images are for illustrative purposes only.